Now,it comes to final process,in this process, it is to make poly film rolls which needs printing or Plain poly film rolls into final product—bags

Cutting. Brief Process is Putting poly film rolls on machine —Converting—Covering glue on adhesive strip—Cutting Bags.

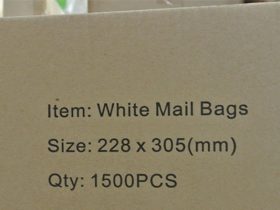

Packaging: Common way is Inner Clear Poly bag,outer pack with carton, Pallet packing(optional)

(usually 50 or 100 pcs /clear poly bags, then 200 or 500 or 1000 pcs / per carton)

Warehouse: we are now using new modernized warehouse,which allow us to store impressive amount order volume.

Currently we own 29 sets bag cutting machines with very fast speed and precise cutting technology. monthly production capacity reach 90 million pcs, which is very impressive production capacity.

With all these, we are confident to provide our clients a long-term stable high quality product, as well as stable and fast delivery requirements